Vacuum Pump

For any fusor work, a two-stage mechanical vacuum pump is required, capable of pumping down to the area of 10 or 20 microns, and preferably lower. We managed to find a suitable second-hand pump on Ebay – a Leybold D16A. After several oil changes and flushings, and after replacing a broken fan on the motor, it seems to meet our requirements. Leybold specifications say that a D16A is capable of pumping around 14 cubic feet per minute, which is more than we actually require, but nice when pumping a large chamber all the way down from ambient.

Our Leybold D16A two-stage vane type vacuum pump.

We intend to supplement the Leybold pump with an adsorbtion pump sold by Kurt J Lesker – a Micromaze. Hopefully this will allow us to achieve a vacuum in our fusor of around 1/10th of a micron (.0001 Torr) before we start backfilling with Deuterium. (We anticipate that actual fusion will take place with a deuterium-filled fusor held at a vacuum of around 5 to 20 microns. This will be accomplished by balancing a constant flow of Deuterium into the fusor with constant evacuation by a throttled pump.)

By utilizing the Micromaze, a diffusion pump will hopefully not be required.

Our Micromaze adsorbtion pump from Kurt J. Lesker.

Update: The micromaze did not seem to work out to create and maintain the lower vacuum that we needed to do fusion. A 2 inch Veeco diffusion pump became available on eBay at a reasonable price, and we bought it. We were lucky in that it was in good shape and complete. The relatively small 2 inch size is larger than we need, but diffusion pumps even as small as 2 inches do not appear frequently on eBay.

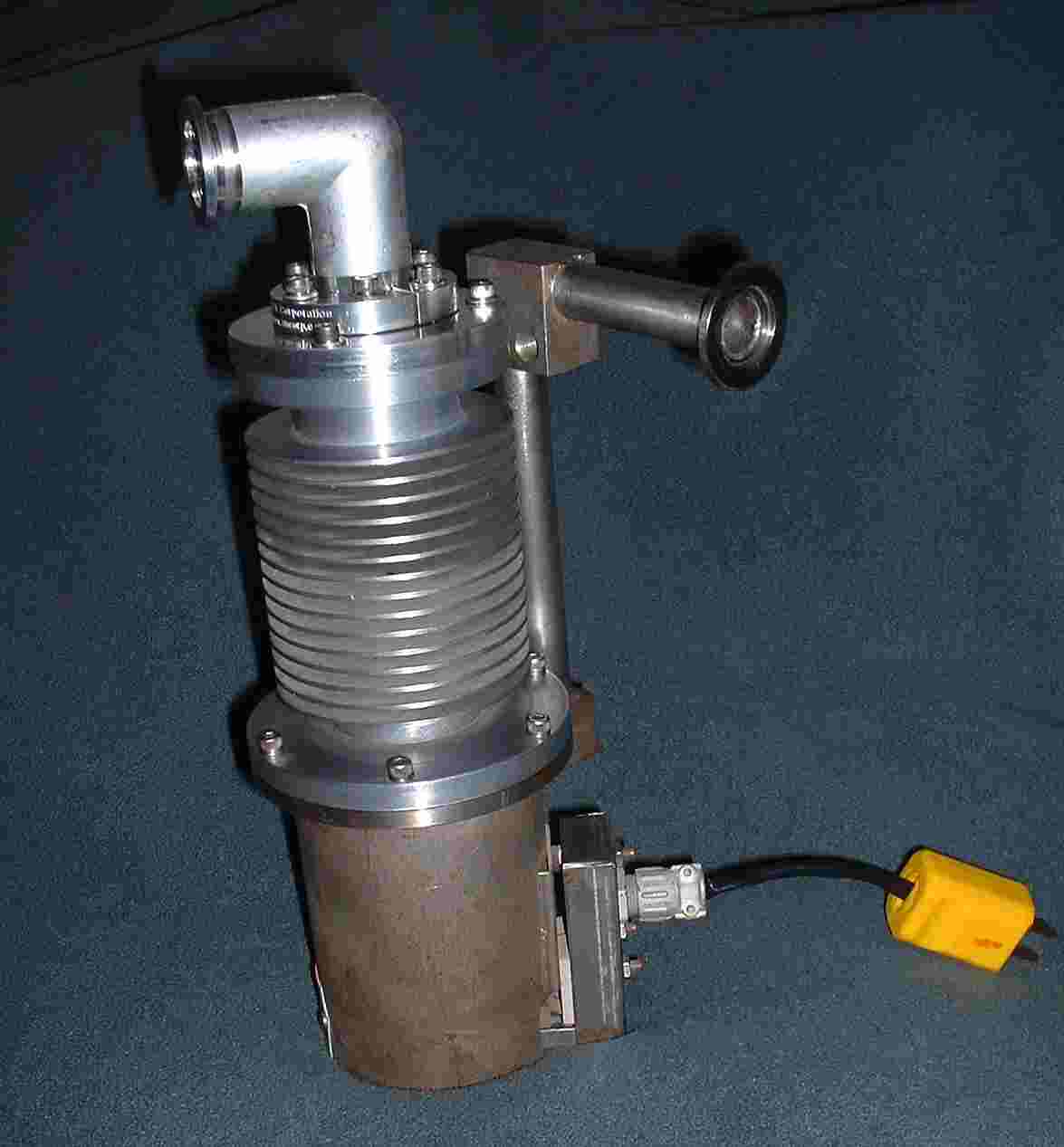

Diffusion Pump

We were able to obtain a 2 inch Veeco Diffusion pump from eBay for a very reasonable price. Diffusion pumps have no moving parts but have an electric heater which boils a special type of oil in the base of the unit. The resulting vapour and oil droplets are sprayed from the top down through several openings in an arrangement known as a Christmas tree. The result is that gas molecules get trapped and moved down toward the outlet of the pump, where there is a connection to the inlet of a conventional vane type “roughing” pump.

A diffusion pump can easily lower the pressure several orders of magnitude below the vacuum created by the roughing pump. The Leybold is still required, of course, to create the initial vacuum of, say, 10 to 20 microns.

Our Veeco pump was in good shape and relatively clean when we received it. We did several required modifications besides taking the unit apart and cleaning it further:

1. We had a QF-25 flange welded onto the pump outlet to facilitate connecting it to our Leybold pump.

2. We changed the electrical connector to a standard North American 120 volt plug.

3. We fabricated an adapter to allow us to connect a QF-25 fitting to the pump inlet.Using a hole cutter we cut a 3 1/2 inch circle of 3/8 inch aluminum. A smaller hole saw made the 1 inch center opening, then the 3 mounting holes were through-drilled and the 6 mounting holes for the bulkhead clamp were drilled and blind-tapped. A Viton O-ring was purchased and installed between the pump and the adapter. It is the brown ring visible in the exploded view below.

Above: Stages in the fabrication of the adapter for the inlet of our diffusion pump.

Above, an exploded view of the completed pump.

The “Christmas tree” is in the center and the new adapter assembly is on the left. On the right, the new QF-25 flange can be seen welded onto the outlet, and an American style 120 VAC electrical connector has been fitted to the heater.

The complete modified Veeco EP 2A-1 diffusion pump with the adapter in place.

This is an air-cooled unit. The upper two thirds must be cooled by a fan when in operation. (Larger diffusion pumps are almost always water-cooled.)

Our “lifetime supply” of diffusion pump oil.

Although relatively expensive, a good grade of synthetic diffusion pump oil causes virtually no backstreaming to worry about. One filling of the pump is approximately 50 cc, and it should last a very long time, so we have plenty to spare!.

![]()